Tinplate metal black glass beer bottles cap

Material Analysis

Beer is a special alcoholic drink that contains a lot of carbon dioxide, which is produced by the yeast in beer. People like to drink beer in summer because there is carbon dioxide in it. Carbon dioxide will be released soon after drinking it into the human body, thus taking it away. The heat inside the human body will make people feel cool, and with the release of gas, it can also impact the inside of the oral cavity, stimulate the oral cavity, give people a pleasant stimulation, also known as the killing power, and bring out some bacteria. Therefore, when drinking beer, people like to gulp, so that more carbon dioxide can be inhaled, resulting in a comfortable taste, which is also the unique flavor of beer.

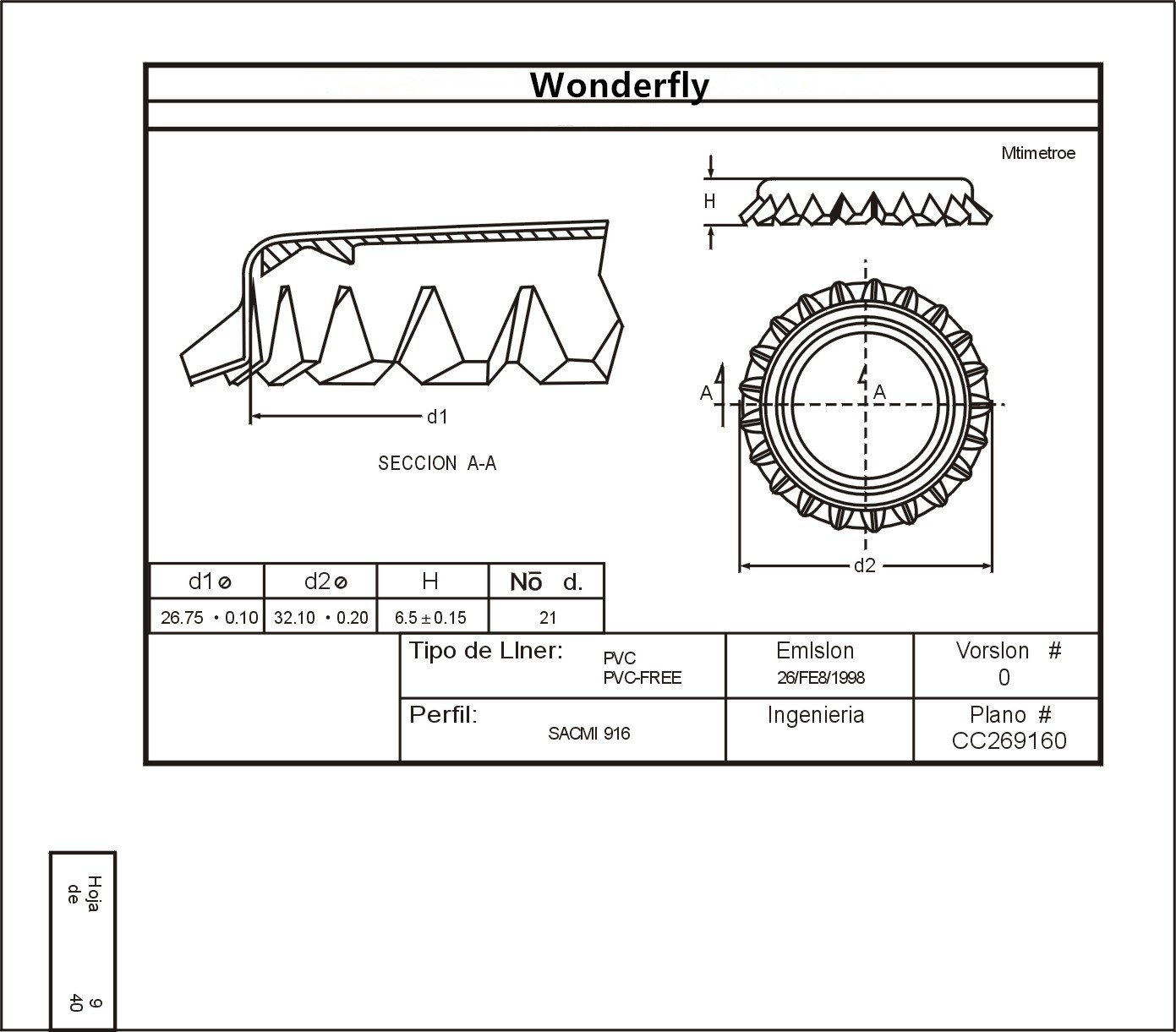

Because beer contains carbon dioxide, there are two basic requirements for the cap of beer, one is to have good sealing, and the other is to have a certain degree of bite, that is, the so-called cap must be firm. This means that the number of pleats on each bottle cap should be proportional to the contact area of the bottle mouth to ensure that the contact surface area of each pleat can be larger, and the wavy seal on the outside of the bottle cap can increase friction and facilitate On, 21 teeth is the best option for both requirements.

Beer crown cork is widely used in beer ,juice ,soda drink and water glass bottles . Top color and logo is good way to show your brand and product feature . The pry off crown cap and twist off crown cap are also used with high quality PE liner . The cap size is standard 26mm . This is the international standard size, which can be well used in glass bottles, with a perfect seal to ensure the taste of the product. If necessary, high-temperature materials can also be customized for high-temperature sterilization products to fully meet various requirements.

Product Specification

| Name of the product | crown cap | Number of Flutes | 21 | |

| Liner | PE | Pieces per Carton | 10000 | |

| Material | Tinplate and ferrochrome plated | Carton Weight (KG) | 25 | |

| Inner Dia(min.) (mm) | 26.75±0.03 | Carton Dimension | 55*35*30cm | |

| Cap Height (mm) | 6.00±0.07 | Type of printing | Customize colors | |

| Out Dia.(mm) | 32.10±0.20 | Packaging | White poly bag , then packed in carton . | |

| Usage | Bottles.beer,Water.Juice,soft drink | Feature | Non Spill | |

| Customized Order | Accept | Place of Origin: | Shandong,China | |

| Brand Name | Wonderfly | Model Number | WDF-02 | |

| Color | Customized | Size | 26mm | |

| Application | Bottle usage | MOQ | Pure color:100,000pcsCustom logo:

300,000pcs |

|

| Logo | Custom logo | Sample | provided | |

| Packaging&delivery | Packaging Detail.10,000 pcs /carton . First , white poly bag ,then packed in carton . | |||

| Port | Qingdao,Tianjin | |||

Parking And Delivery

Lead Time

| Quantity(pieces) | 1 - 100000 | >100000 |

| Est. time (days) | 7 | To be negotiated |

Picture Display

【Patent Description】

Chrome-plated plate and method of making the same, crown cover technical field

The invention belongs to milk steel technical field, be specifically related to a kind of chrome plate and manufacture method thereof, crown cover.

【Background technique】

Due to having good sealing performance, crown cap can keep pressure and quality and taste unchanged for a long time, so it is widely used in industries such as beer and carbonated beverages packed in glass bottles, and wherein beer industry is the main. The crown cover is a stamped tinplate, generally made of T4 material with a thickness of 0.22~0.24mm and a hardness of HR30Tm of 61 ± 3. There are two types of surface plating: tin plating (SPTE) and chrome plating (TFS). With the development of the food packaging industry, it is proposed to reduce the thickness of the crown cover, increase the strength, and use low-cost chrome plating (TFS) instead of tin plating.

The crown cap is a versatile product that can be used for beverages such as beer, juice, sparkling water, etc. Belongs to standard size, the pattern is beautifully printed, and can be customized as required. Product quality first, short delivery time .

Picture Display

The production process and quality of the crown cap:

Bottle caps: Bottle caps are bottle caps with sizes, materials of various sizes, bulking, and liner processing to form a bottle cap with a certain outer diameter, height, and skirt teeth.

Production environment